|

If you are going to do a job, it pays to plan ahead, prepare your workspace materials and tools and do the job right the first time.

Especially if it’s a job with expensive materials, or meant to be a permanent part of your home – like the built-in bookcases I’m working on right now.

|  |

So I thought I’d share with you some of the little “workshop helpers” that can make a huge difference on a project, and many can be made easily yourself.

Especially if you are working alone, the “helpers” can make a difficult task much easier!

Assembly Blocks

This assembly block is quick and cheap to make out of scrap materials!

Besides helping to ensure that my bookcase corners are square, it is like an extra set of hands! After placing the MDF into the block, the boards stay in place, allowing me to grab my glue, drill and screws before squaring everything up and adding the corner clamp to the top. I like using both the assembly block and corner clamp to hold everything in place!

I just used glue and screws on some scrap pieces of wood. Make sure you set it up square with representative pieces of your material (3/4” MDF for me) before you glue and screw it all down.

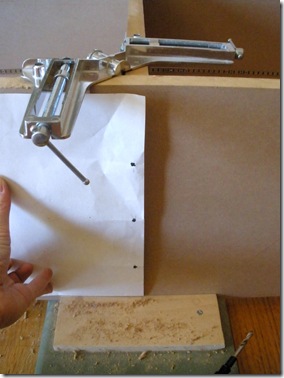

Drilling Template

I need to whip one of these up out of acrylic or scrap wood, but a simple piece of paper works too! I’ve marked on the paper where my pilot holes need to be drilled. Then I just use an awl, pen or the tip of my drill bit to mark the wood before I drill.

|  |

Because MDF “blows out” so easily, it is really important to make sure your pilot holes are drilled into the middle of the board edge! Without this guide I’m sure I would’ve put a hole to close to the edge! This is also a useful tool if you want all your pieces to look uniform.

Something similar works wonders when attaching cabinet hardware.

Sawhorses

See this post for instructions on building your own DIY adjustable height storage sawhorse.

Ripping and Cross-cut Table and Rip Fence

Not everyone will need an extra large surface for their table saw. But since I’m using 4x8 foot sheets of MDF I needed this badly! The instructions for the table and rip fence are here. I also have a foldable table placed behind the saw to catch the output.

With the saw in this position, I can rip this long sheet of beadboard. I just cut along one of the “beads”, but I could also have used my 8’ circular saw rip fence and some clamps as a guide.

For trimming off that extra inch, I use the table’s metal rip fence.

|  |

|  |

Ripping

With the saw in this position, I can cross-cut my beadboard to fit the height of my bookcases.

|  |

|  |

Cross-cutting

There are a few problems with this enormous table. My saw is on its own stand, so the saw and the table move independently – this is very bad when using the 2x4 rip fence – the cuts can be inaccurate. I have been pretty lucky and all my cuts have been fine, but if accuracy was really important, I would find a way to firmly attach the table to the saw and minimize the movement.

Also, the on/off switch is hard to reach. This is a huge no-no as it can be dangerous. I plan to built an emergency push bar stop that extends out past the edge of the table. (I’ll share that with you when it’s finished!)

This is only a tiny subset of the “workshop helpers” that you can use… there’s sure to be a few more posts like this one in the future!

New to Pregnant with power tools? Don't miss a post and subscribe here...

Email Updates

Email Updates

Thank you Christin!!! I love your sawhorses and I think I finally found my perfect adjustable knitting machine table... ;-)

"Groeten uit Amsterdam"

Palma

Hi thanks for sharing thiss